On a CIO Talk Radio podcast titled “What the Internet of Things Means for Manufacturing,” Gartner analyst Simon Jacobson highlighted immediate challenges and opportunities that will accompany the increasing connectivity of the modern world.

On a CIO Talk Radio podcast titled “What the Internet of Things Means for Manufacturing,” Gartner analyst Simon Jacobson highlighted immediate challenges and opportunities that will accompany the increasing connectivity of the modern world.

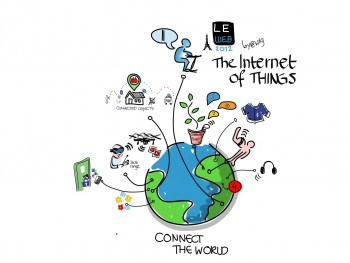

The Internet of Things (IoT) is the expectation that our world will soon be connected in a system that erases boundaries between digital and physical worlds. The digital world will become integrated even further than it is now with our communication, data production, operations, and most other parts of our lives.

Jacobson says that there has been a move towards individualization and mass customization of products. In order for orders to meet specific customer requests, players on all rungs of the management ladder have to be sure that they are able to customize orders in time. In order to do so they will need to use technology to help them create products with shorter lead times and fewer defects, as well as to account for quick changeovers and low inventories of generic products.

The key challenge of IoT will be its safety and protections. Security must blend mobile, cloud, and technological security with physical and industrial controls already in place. Electronic and physical security features must become intertwined in order to protect companies from threats, viruses, break-ins, and external factors that could cause harm to the company.

While automation with a human touch has been key in industry, as workers will stop the line if the product is out of spec. Quality checks are usually conducted in person so as to measure tolerances and determine defects. Jacobson predicts that the transition to new IoT technologies will gradually shift this process to become an automated one, freeing up worker time and determining problems more quickly. Process performance will be key to a high ROI.

Predictive maintenance tools can be used to guarantee certain outcomes and levels of satisfaction for the customer. This will reduce unexpected downtime, will save repairs, save labor costs, improve output, and will overall prevent issues from occurring during processing.

Production will play a much bigger role in the manufacturing value chain once IoT technologies are integrated. The focus will not be on costs of production but on acceleration and innovation on the factory floor. It will be easier to implement milestone steps in the industry with common integrated network flow.