Environment, Health, and Safety (EHS) programs are undergoing a fundamental shift—from static, paper-based processes to dynamic, data-driven systems that actively surface risk and drive action.

While many organizations have taken steps toward digitization, simply converting paper forms into PDFs does not solve the core challenge EHS teams face today: making safety data accessible, usable, and actionable.

This is where AI can be transformational. While AI has played a role in industrial and safety systems for decades, recent advances, particularly large language models (LLMs), now make it possible to apply AI across everyday EHS workflows like inspections, incident reporting, and chemical management at scale. This shift unlocks insight from the unstructured data and natural human language where much of safety information lives.

Below is a practical framework for understanding how AI can be applied across EHS workflows, and where it delivers the most value.

Reality Check: Where AI Excels and Where AI Struggles in EHS

AI is powerful, but it is not a magic wand. In EHS, its value comes from applying it intentionally: using it where it accelerates work, and constraining it where human judgment and accountability must remain central.

AI is most effective when it supports repetitive, text-heavy, and reviewable work, such as:

- Organizing large volumes of unstructured data from inspections, incidents, SDS documents, images, and video

- Identifying patterns and recurring issues (e.g. unsafe practices on video) that are difficult to surface manually

- Drafting initial summaries or documentation for human review.

Used this way, AI can significantly reduce administrative burden and help EHS teams focus on decision-making rather than data processing.

Risk emerges when AI outputs are treated as authoritative rather than assistive. General-purpose AI does not fully understand site-specific context, lacks situational awareness for independent decisions, and can confidently generate inaccurate or incomplete information (“hallucinations”) if not properly constrained.

These limitations are especially critical in EHS, where accuracy, traceability, and accountability are non-negotiable. This is why AI must function as a supporting layer within EHS workflows—augmenting human expertise rather than replacing it.

How to Design AI for EHS

Because of these constraints, AI for EHS must be designed differently than general-purpose tools. In regulated environments, the goal is not automation for its own sake, but acceleration without loss of accountability.

In practice, this requires three deliberate design choices.

Choice #1: Data Quality Matters

The reliability of any AI output is directly dependent on the quality of its input. Public models are trained on the “entire internet”, which is vast, but largely unverified, general, and irrelevant. For EHS, AI should be grounded in verified regulatory frameworks, proven safety methodologies, and structured operational data from high-quality, domain-specific sources rather than internet generalizations.

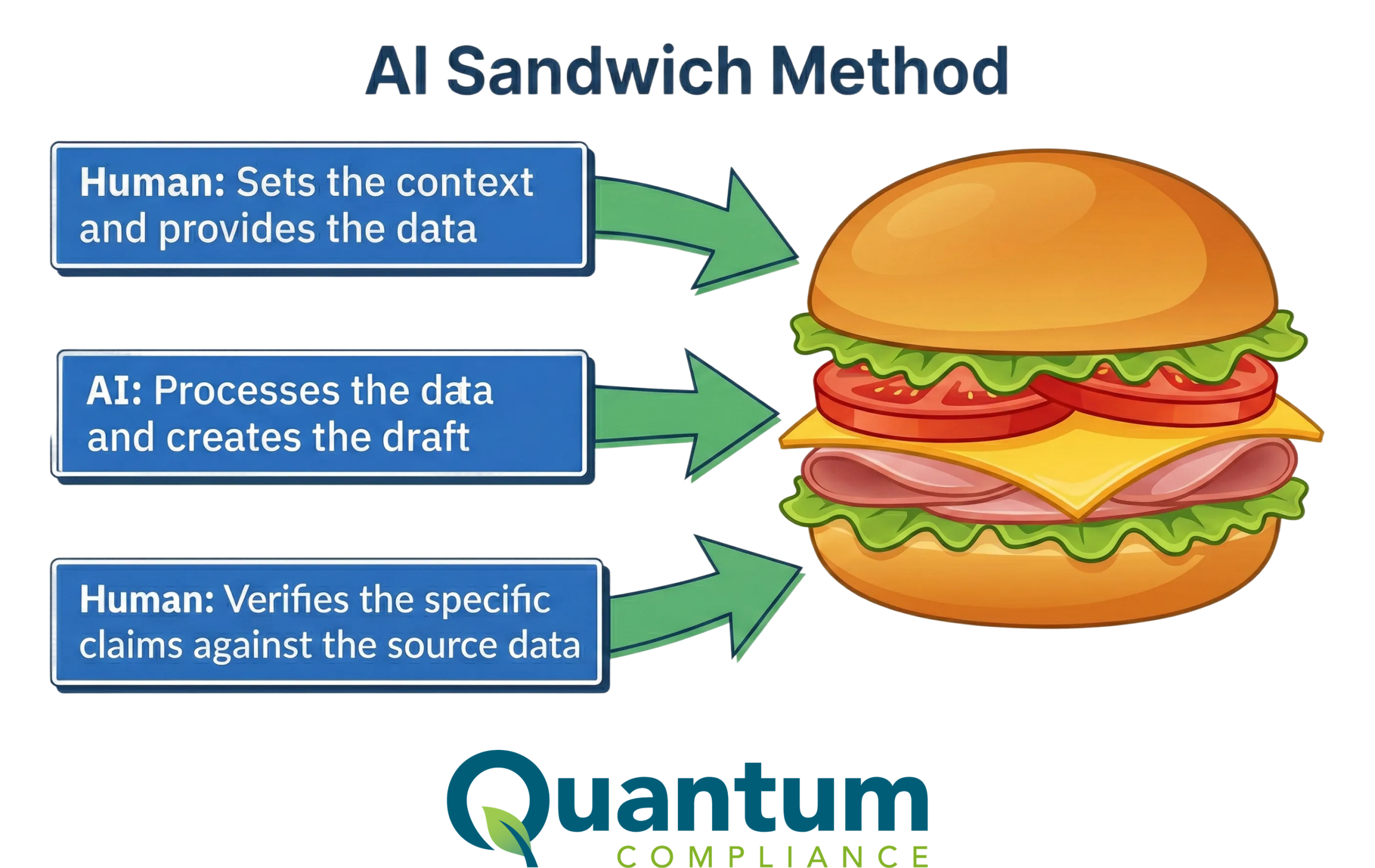

Choice #2: Human verification must remain part of the workflow

“Hallucination” in AI occurs when a model confidently generates false or nonsensical information. One effective way to enforce this is through the Sandwich Method (illustrated below):

- The Top Bun (Human): You set the context and provide the data

- The Meat (AI): The AI processes the data and creates the draft.

- The Bottom Bun (Human): You verify the claims and ensure accuracy before submitting the record.

Choice #3: AI must live inside the EHS system of record.

Efficiency and compliance rely on seamless integration. Using a tool that sits outside your daily system adds friction and reduces adoption.

These principles are not theoretical—they reflect how we design and apply AI within the Quantum EHS platform across inspections, chemical management, and incident workflows.

Where EHS Teams Can Start

With these guardrails in mind, many EHS teams begin applying this human–AI–human approach in small, low-risk ways. These early uses don’t replace formal systems, but they illustrate what responsible AI use looks like before it scales. Here are examples of where AI can be useful without replacing judgment or creating official records:

Faster toolbox talks: Paste a regulation or SOP into an LLM to create a clear, 5‑minute toolbox talk for frontline workers.

Custom safety visuals: Image‑generation tools can quickly create site‑specific posters—moving beyond generic clip art.

While these approaches work well for exploration and preparation, they quickly reveal their limits as soon as AI outputs need to be trusted, shared, or tied to compliance records. At that point, the same principles must be applied at the system level: across inspections, chemical management, incident reporting, and corrective actions.

Applying AI Principles Across EHS Operations

The principles above are not theoretical. They shape how AI can be applied responsibly across core EHS workflows.

1. Inspection AI: Automating the Analysis

Inspections often include hundreds of questions. Manually reviewing every finding to assess severity, regulatory violation, and next steps is time-consuming and prone to error, slowing the transition from identification to correction. Applying AI to summarize inspection data, classify hazards, and map findings to relevant regulations helps teams focus on prioritization and corrective actions, while keeping final decisions in human hands.

Inspection Data Summary

Regulatory Alignment and Corrective Actions

Risk & Hazard Classification

This drastically reduces administrative burden while ensuring every finding is mapped to the correct regulation and assigned a clear action item, ensuring nothing slips through the cracks.

2. SDS Reader: From Unstructured to Structured

One of the biggest headaches in EHS is managing Safety Data Sheets. These are complex documents with 16 sections, and each manufacturer produces it differently. They contain critical information, but when stored as static PDFs or papers in a file cabinet, they are difficult to analyze at scale. Using AI to extract data from the SDS and structure it enables teams to search across chemical inventories, identify hazards quickly, and respond more effectively.

Instead of manually entering data for a single SDS into an excel document, AI can extract the relevant information and places it directly into the database fields.

It transforms your chemical inventory from a digital file cabinet into a dynamic, searchable database, allowing for instant reporting on specific hazards or chemical properties.

3. Speak-to-Report Incident Reporting

These same principles apply not only to how safety data is reviewed, but also to how it is captured in the first place. The “old way” of reporting incidents causes friction: work stops, forms are lost, and handwriting is often illegible. Applying AI to convert natural language—such as voice descriptions—into structured data helps capture richer information while reducing friction for frontline workers.

With AI, we remove the barrier to technology, allowing workers to report naturally in a method they are comfortable with. This results in higher engagement from the workforce and significantly richer, more detailed data for safety managers.

From Documentation to Prevention

These principles reflect how we design and apply AI in the Quantum EHS platform. By moving from paper to pattern, we aren’t just digitizing; we are building a system that sees, listens, and analyzes, resulting in a safer, more efficient culture.