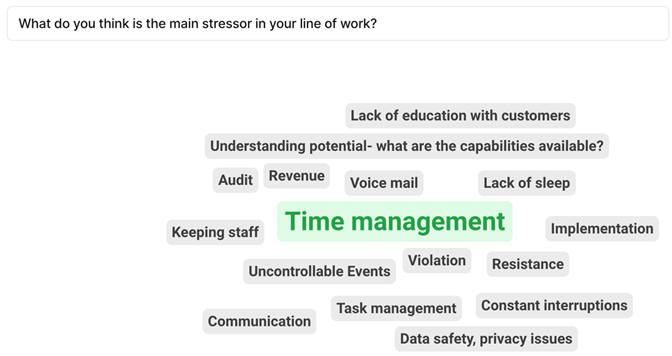

EHS leaders today are facing a difficult reality: more responsibility, more data, more expectations — and often fewer resources. The work is complex, safety is at stake, and every decision must hold up to regulatory and operational scrutiny. Yet much of an EHS professional’s time is still consumed by manual documentation, searching for compliance details, re-writing corrective actions, chasing stakeholders, and trying to make sense of inconsistent data across sites.

It’s not that the work is impossible, it’s that the workflow has become unsustainable.

AI in EHS isn’t about automation for the sake of novelty. It’s emerging because the current system creates inefficiencies that hold back prevention, slow down response, and limit the impact of safety teams. When implemented in practical, responsible ways, AI can directly support EHS professionals in the areas where they need the most help: documentation, clarity, consistency, and decision-quality.

Below, we break down the real problems EHS teams face, what modern AI solutions can actually do, and the impact EHS organizations can expect when AI is intentionally leveraged to support EHS leadership.

The Pressure on EHS Teams Has Never Been Higher

EHS professionals consistently report the same challenges across industries and company sizes:

1. Too Many Tasks, Not Enough Time

Documentation, inspections, observations, training follow-ups, audits, corrective actions: every task requires accuracy and attention. But EHS teams are frequently understaffed, stretched across multiple sites, and required to respond instantly to emerging issues.

2. Disconnected Systems and Siloed Data

Spreadsheets, PDFs, emails, paper forms, shared drives, and legacy systems make it difficult for leaders to maintain a clear picture of risk.

3. Inconsistent Reporting and Documentation Quality

What one inspector writes in a report may look very different from their peers. Critical details are sometimes missing, descriptions vary widely, and corrective actions may be vague or incomplete, all of which introduces risk and inefficiency.

4. Difficulty Finding the Right Regulatory Information Quickly

EHS teams spend hours searching through OSHA standards, internal procedures, or equipment guidelines. In fast-moving environments, that slows down good decision-making.

5. Pressure to Be More Strategic with Limited Resources

Executives want predictive insights, proactive risk reduction, and clear ROI. But EHS teams are often bogged down in reactive tasks that consume their limited time and energy.

These challenges create a gap between what EHS teams want to do (build a strong safety culture, prevent incidents, empower employees, etc.) and what they can realistically accomplish within existing constraints.

This is the gap where AI can make a meaningful difference.

Where AI Fits in EHS and What It Actually Does

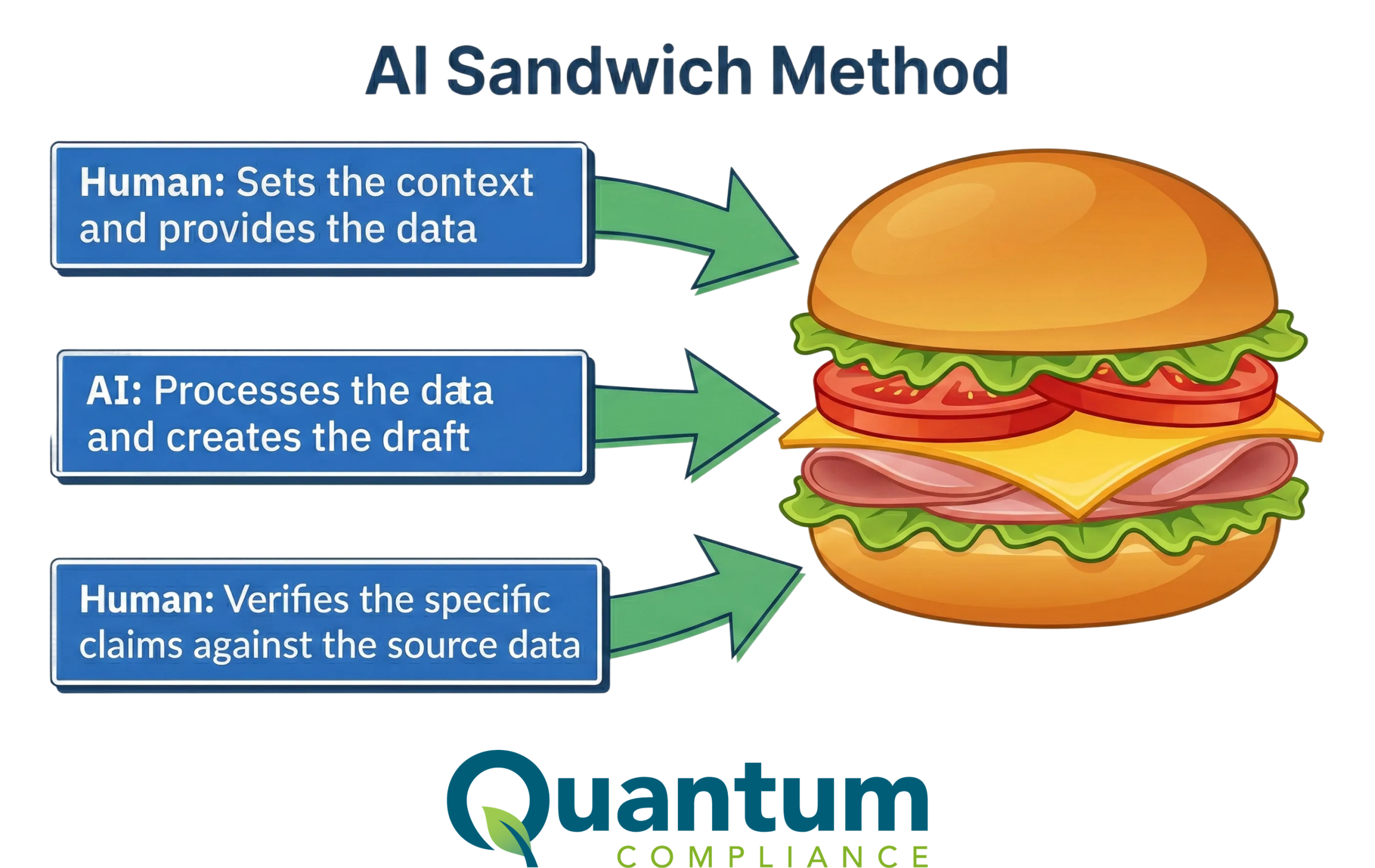

These challenges are not new—but the tools available to address them are.AI in EHS is not magic, and it is not a replacement for human expertise. What it is becomes powerful when built to solve real, day-to-day EHS burdens.

1. Smart Analysis: Turning Documentation into Clear, Complete Records

EHS reports are often rushed due to time pressure, and there are often missing and unclear details in the report. Additionally, employees are inconsistent with how they write – some write succinctly, some write detailed paragraphs. AI generates consistent, thorough descriptions for inspections, observations, or incident reports based on short notes, photos, or key details provided by the user.

In this way, every inspection or hazard observation contains the right level of detail, language becomes standardized, and leaders can analyze data cleanly because the input quality is consistent. Additionally, EHS professionals save hours each week on administrative rewriting and editing.

2. Smart Reference: Instant Regulatory and Standards Lookup

EHS teams often spend large portions of their data searching for applicable standards, making it easy to misinterpret or overlook a requirement when moving quickly. At the same time, stakeholders outside EHS often need “proof” or a “cited requirement” that shows why change is necessary. AI surfaces relevant regulatory information like OSHA references, internal policies, equipment requirements based on the details of a hazard or task.

As a result, compliance referencing is automated, corrective actions and recommendations are credible due to clear citations, and teams reduce risk of non-compliance caused by oversight or outdated information. EHS Managers can also respond more decisively and confidently to questions from supervisors, auditors, and leadership.

3. Smart Suggest: Guided Corrective Actions and Recommendations

Employees often identify hazards but don’t know the best corrective actions to take, making them overly generic (“clean area”, “retrain staff”, etc.). EHS staff then spend considerable amounts of time rewriting vague actions into something tactical and practical. AI recommends appropriate corrective actions based on the hazard type, severity, location, and historical data from similar events.

Corrective actions are now specific, targeted, and consistent, and hazards are resolved more effectively and quickly. Data improves dramatically, enabling better trend analysis and reporting. Therefore, even non-EHS employees can produce high-quality, safety-aligned next steps.

The Larger Impact: What AI Actually Changes for EHS Organizations

AI is not just an efficiency tool; it reshapes work.

1. A Clearer, More Predictable View of Risk

With consistent documentation and AI-assisted analysis, leaders gain a system-wide view of hazards, trends, and emerging risks.

2. Better Communication Across Departments

Standardized language and easy-to-share references eliminate confusion between EHS, operations, maintenance, and management.

3. Faster Resolution of Hazards

When corrective actions are clear and automatically drafted, hazards get closed out faster, reducing incident potential.

4. More Time for Proactive Safety Work

By removing repetitive tasks (rewriting reports, hunting for standards, drafting corrective actions), EHS teams can refocus on training, prevention, and strategic safety improvements.

5. Stronger Safety Culture

Employees feel more supported and more confident reporting hazards when the system helps them contribute high-quality information.

6. Audit-Ready Consistency

AI helps produce clean, standardized, regulator-friendly documentation at scale, even across dozens of sites.

The Bottom Line: AI Helps EHS Teams Modernize Without Losing the Human Element

AI isn’t here to replace EHS expertise — it’s here to multiply the impact of that expertise. When used responsibly, it helps teams document faster, decide more confidently, and act more strategically.

Most importantly, it gives safety professionals more time back to do the work that actually improves lives: training people, supporting the field, identifying risks before they escalate, and building a culture where safety is the shared priority.

EHS teams have always been at the center of protecting people.

AI simply strengthens their ability to do it.